Shannon gets into hot water!

This week, Shannon, a respected plumber from NSW, called me. He was looking at the second hot water circulation pump to fail on a site in six months!

Shannon initially thought he had been sold faulty products from his plumbing distributor. However, two pumps in six months didn't sound right for defective products, though you can never be sure. Shannon sent photos of the pump. However, it looked sound.

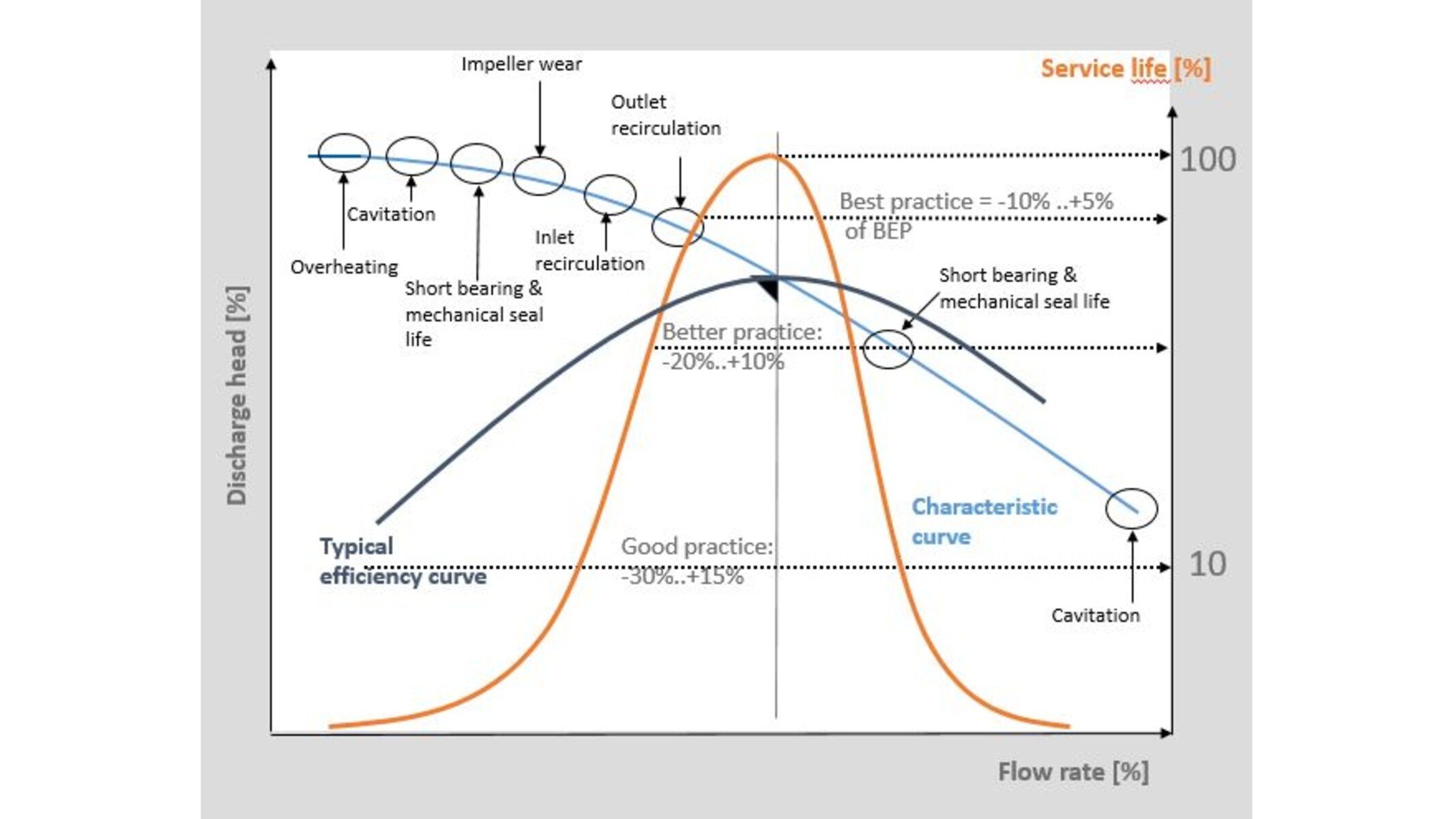

I asked him what system the hot water pumps were running through. It started off in 40mm copper and kept dropping back incrementally all the way to 15mm copper toward the end of the run. Upon review, I could see the pump was running extremely far to the left of the pump's Best Efficiency Point (BEP), likely causing a number of issues.

Upon seeing the issue, I explained what the issue may have been with the pump to Shannon, and he was happy to upgrade the smaller pipe sizes in the system to 32mm copper, which allowed the replacement pump (A REEFE RHC32-80 Hot Water Circulation Pump) to run close to its BEP.

We shall wait for time to run its course to see if this has resolved the issue.